Work area: 3000mm x 840mm

CZ PLUS XXL

The CZ Plus series: the ultimate cutting machine

Thanks to a symmetrical compact structure, even large hides can be easily loaded.

The entire hide can be reached and flattened by either the front or the rear of the machine.

SECTORS

Footwear, Leather Goods, Automotive, Apparel and Furniture.

CONFIGURATIONS

The CZ Plus series can be configured for: single ply synthetic/textile cutting; multi-ply synthetic/textile cutting (multi-ply spread or multi-roll); leather cutting; vision assisted cutting/final trimmin.

Cutting speed that pushes performance to the max

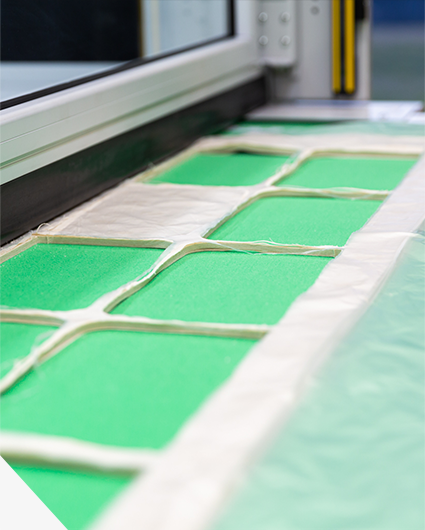

FFD

Foldable Feeding Device

The FFD is one of the innovative elements of the CZ Plus series. The feeder is easily opened by one operator, designed to load textile and synthetic materials. Two practical clamps help the single operator to align and stabilize materials on the feeder, adding precision in cutting process. Productivity is boosted: while the machine is cutting, new material is fed. The feeder is completed by multi rolls supports, which allow the switch from multi plies to multi rolls feeding. The Feeder can be easily folded, and works at its best for leather cutting, both with manual or auto nesting (on-line/off-line).

The FFD is one of the innovative elements of the CZ Plus series. The feeder is easily opened by one operator, designed to load textile and synthetic materials. Two practical clamps help the single operator to align and stabilize materials on the feeder, adding precision in cutting process. Productivity is boosted: while the machine is cutting, new material is fed. The feeder is completed by multi rolls supports, which allow the switch from multi plies to multi rolls feeding. The Feeder can be easily folded, and works at its best for leather cutting, both with manual or auto nesting (on-line/off-line).

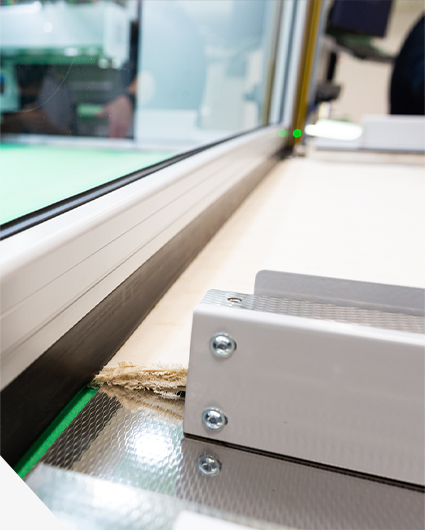

FAS

Front Active Screen

A Front Active Screen automatically closes and opens in parallel with the operator’s activity; while cutting it’s closed, when the operator needs to work on the material, and approach it, it opens. While conveyor moves, it opens automatically. The screen presses the material on the flat table, guaranteeing the stability of the material in the cutting area. FAS assures low level of noise during operating activities, for the benefit of prolonged use.

A Front Active Screen automatically closes and opens in parallel with the operator’s activity; while cutting it’s closed, when the operator needs to work on the material, and approach it, it opens. While conveyor moves, it opens automatically. The screen presses the material on the flat table, guaranteeing the stability of the material in the cutting area. FAS assures low level of noise during operating activities, for the benefit of prolonged use.

RAS

Rear Active Screen

As the FAS, RAS automatically closes during cutting activity, opens at machine idle or while the conveyor is moving and presses the material on the flat table, guaranteeing additional stability of the material in the cutting area. The cutting area is now accessible from the “back” and well of course from the “front”. Together with FAS, RAS gives additional stability while cutting, increasing the number of plies can be cut. The thin frame of FAS and RAS screens, the brightness of glass screen, gives to the operator a close view of the inside of the cutting area.

As the FAS, RAS automatically closes during cutting activity, opens at machine idle or while the conveyor is moving and presses the material on the flat table, guaranteeing additional stability of the material in the cutting area. The cutting area is now accessible from the “back” and well of course from the “front”. Together with FAS, RAS gives additional stability while cutting, increasing the number of plies can be cut. The thin frame of FAS and RAS screens, the brightness of glass screen, gives to the operator a close view of the inside of the cutting area.

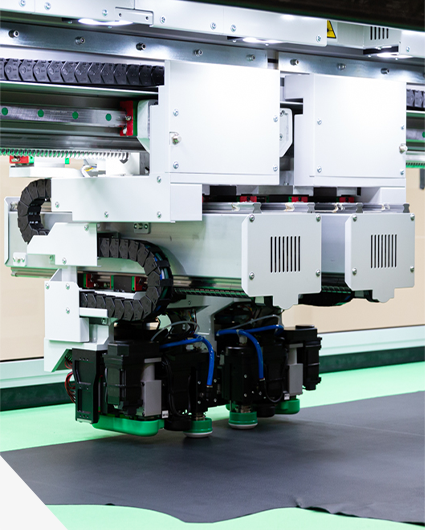

CUTTING WITH HIGHEST QUALITY

& PRODUCTIVITY

The structure of new machines is stronger: the cutting speed gets to limit not possible before. Therefore, the performances are impressive. Interlocking carriages bring the two cutting units to touch each other while cutting. Machines are equipped with new generation heads. Double head support, new punching units.

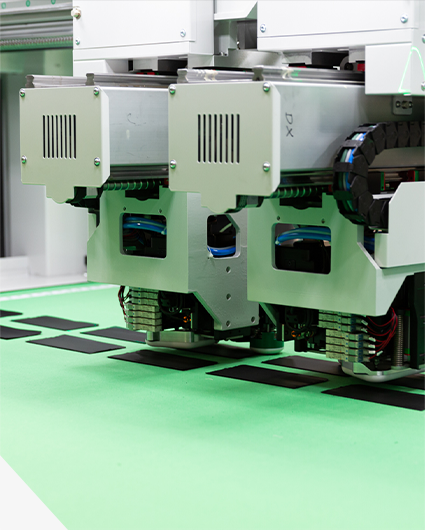

VISION SYSTEMS FOR MORE INDUSTRIAL APPLICATIONS

With the CZ Plus series it is possible to have the most effective vision system that Comelz ever made in combination with the productivity of the double head machine. CZ Plus equipped with vision can cut textile/synthetic materials with drawings, logos, pre-printed images or roll of engineering mesh or similar. Final trim of pre-assembled parts can be also done.