We are a leading manufacturer of leather

splitting machines, known for our

quality, reliability and innovation.

THE STORY OF CAMOGA

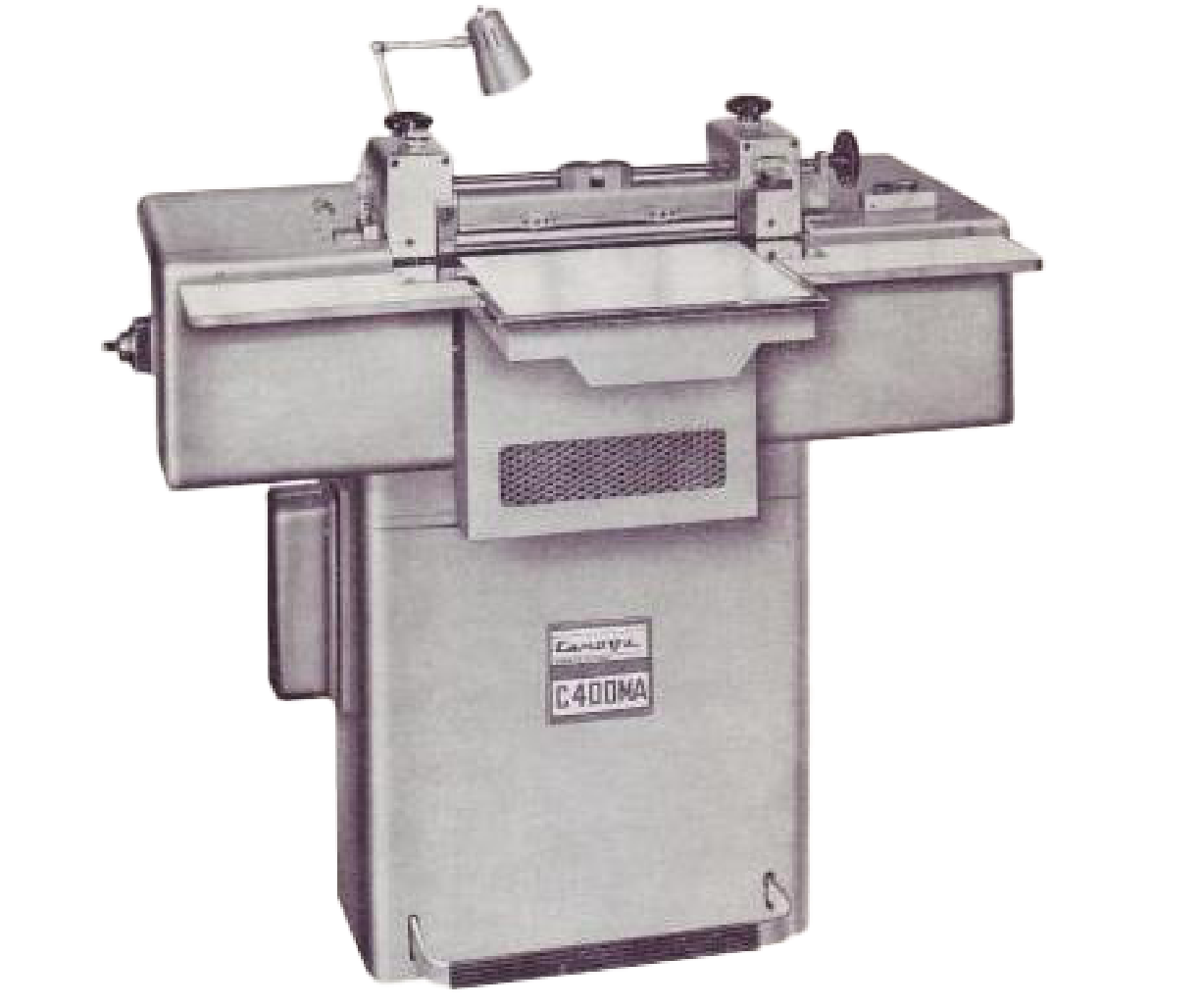

Camoga, founded in 1948, has built

from the beginning, machines for the production of footwear and leather goods.

In its first decades of operation, Camoga S.p.A. also built machine tools and this generated a high-precision mindset.

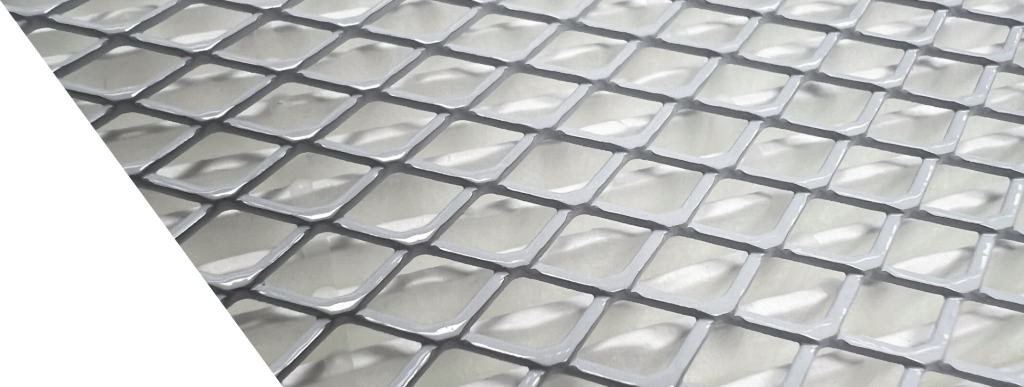

Its machines are known all over the world for their quality and reliability: this is why it is considered the leading company in the construction of ‘leather splitting machines’ (to reduce and equalise the thickness of leather)

The Principles of Camoga

Camoga Splitting Machines

Our Certification

CAMOGA

TODAY

Our machines are designed

and built according to the basic principles

of all Camoga products:

Quality in materials and component construction for high performance and longevity.

Easy operation and maintenance to limit unproductive stops and operating costs.

Ergonomics, their working position was developed to reduce fatigue.

Continuous search for environmental impact reduction, both in terms of consumption and in waste and dust emission/collection

Highly reliable, cost-effective and flexible machines for high productivity, used in the manufacture of footwear, leather goods, belts and related items, in furniture factories and automotive components. The wide range of machine models available meets all requirements, from the craftsman’s workshop to large-scale industry.