CZ PLUS EXTENDED

Single-ply cutting system with artificial vision for patterned fabrics

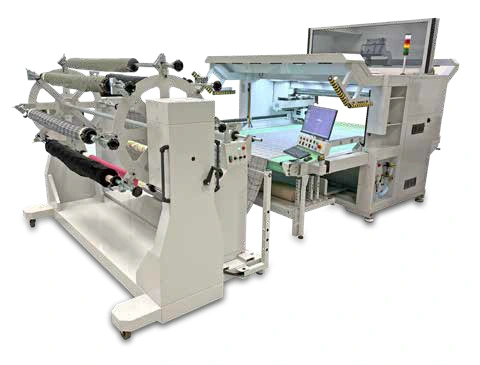

CZ Plus L Extended is a single-ply fabric cutting machine designed to deliver high precision and productivity. The Comelz Vision system automatically recognizes and aligns placed and all-over prints, checks, stripes and logoed materials, significantly reducing manual operations.

- Fast and precise cutting on any fabric

- Automatic recognition and alignment of any pattern

- Complete equipment for every production requirement

- Automatic or free manual nesting

- Reduced labor requirements and operating costs

- Compact footprint

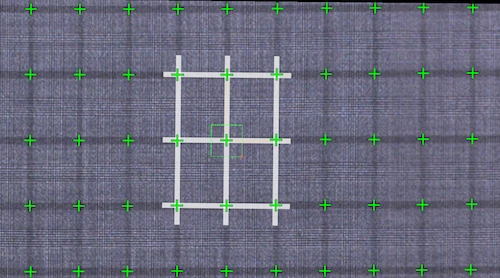

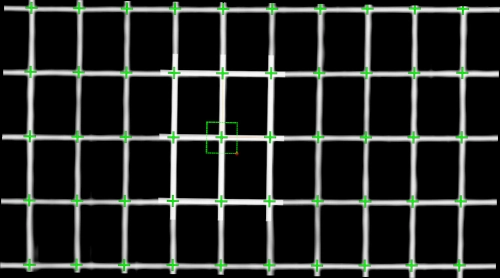

Artificial Vision

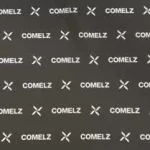

Artificial intelligence ensures precise recognition of logoed fabrics, checks, and stripes, preserving pattern continuity across the different parts of the pattern and guaranteeing flawless alignment in the finished garment.

Continuous cutting combined with automatic vision enables accurate interpretation of all-over graphics, delivering extremely high precision while minimizing waste.

The vision system analyzes the material in its real condition immediately before cutting, detects any defects, and excludes non-conforming areas, enabling prompt operator intervention.

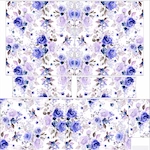

Original

AI Generated

Patterns and Materials

With CZ Plus Extended you can cut:

Placement Prints

Automatic recognition and precise alignment of placed graphics on each piece.

Repeated Patterns

Automatic recognition and alignment of repeated patterns with graphics and logos.

Checked Fabrics

Millimetric management and alignment of checks, even with subtle color variations.

Striped Fabrics

Pattern continuity control to ensure stripes match perfectly after sewing.

Comelz material control technologies

- Fast material classification

New materials can be classified in just a few clicks, either from the office or directly at the machine. - CFSS – Comelz Fabric Straightening System

Advanced system that automatically replicates the fabric straightening results traditionally achieved using a pin table. - CFRS – Comelz Fabric Resizing System

Automatic management of material drop and material change, with independent settings for warp and weft. - CFDS – Comelz Fabric Defect System

Automatic recognition of defect markers. Nesting, performed directly on the machine, is adjusted in real time to avoid defective areas of the fabric.

Why CZ Plus Extended

Accurate pattern reconstruction

Fast, efficient and highly accurate cutting of checks, stripes, all-over and placed prints on any type of fabric.

Less material waste

Maximum optimization enabled by a high-precision artificial vision system.

Operational efficiency

Significant reduction in labor through the automation of manual, error-prone activities.

Higher productivity, zero downtime

Automatic nesting performed directly on the machine, with no waiting times.

Versatility for every requirement

Designed to meet any customer need, it handles every type of cutting process and supports the main standard file formats (DXF, HPGL/PLT).

Production continuity

Global support ensured by more than 40 Comelz service centers worldwide.

Higher Productivity

- Simultaneous operation of the two cutting heads

- Complete configuration for managing any type of cutting process

- Machine operation by a single operator

- Nesting performed directly on the machine thanks to the laser projector

- Wrinkle removal without stopping the machine

- Flexible loading of rolls, fabric pieces and mixed materials, with integration of systems for handling large and heavy rolls

Operator Autonomy

CZ Plus Extended is designed to be managed directly by the operator, minimizing the need for intervention from Comelz technical support.

Advanced configuration functions – such as setting filters for pattern and logoed fabric recognition – are intuitive and can be handled independently, without requiring specialized skills.

Routine maintenance operations, including replacement of the cutting belt, are also designed to be quick and straightforward, helping reduce downtime and ensure continuous production.

Sustainability and Operator Well-being

CZ Plus Extended is designed to promote a more sustainable and comfortable production environment.

The cutting process eliminates the need for support materials such as paper or plastic (cartene), reducing waste and disposal costs.

The automatically opening cover helps reduce noise levels, improving operator comfort.

Completing this responsible approach, Comelz uses exclusively renewable energy, reinforcing its concrete commitment to efficient, environmentally responsible, and future-oriented manufacturing.

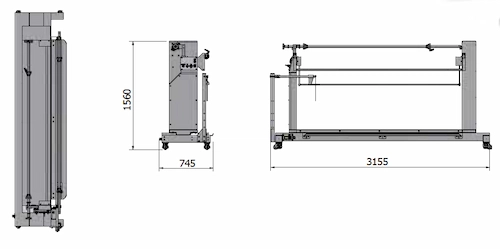

Technical Specifications

- Compact, single-block construction

- Easy to transport and reposition

- No floor anchoring required

- Compatibility with DXF, ISO, HPGL and GBR file formats

Working area (L x P)

1800 x 900 mm oscillating blade

1900 x 900 mm rotating blade

Cutting speed: 60 m/min

Maximum punching frequency: 600 colpi/min

Air supply: 300 NL/min at 6 bar

Power supply: 3 phase 400V – 50/60 Hz

220V – 50/60 Hz (op)

Maximum power consumption: 20 kVA

Accessories

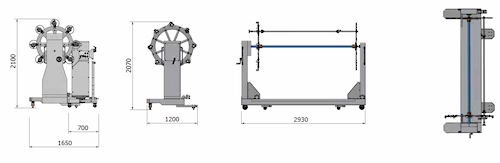

RA Unwinder

Zero-tension roll unwinder with automatic selvedge alignment (pole).

RR Revolver

Cup holder revolver (max. 8 poles) combined with the binder RA

RD Unwinder

Zero-tension roll unwinder with automatic selvedge alignment (cradle)