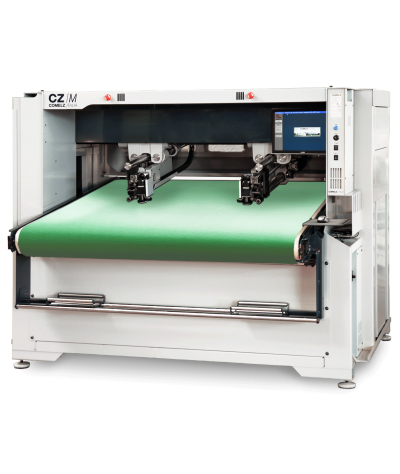

Work area: 1500mm x 850mm

CZ M

CZ M: the most complete solution

to meet the wide variety

of needs of cut

The width of the working field offers high flexibility in compact dimensions. It can process entire small and medium hides in one step or up to large half hides in a longitudinal way in multiple steps.

SECTORS

Leather Goods, Footwear

CONFIGURATIONS

Depending on the hides, everybody can choose the correct width of the conveyor belt among sizes M, L and XL, respectively 1.6, 2.0, 2.4 meter.

Authentic innovation

and high production

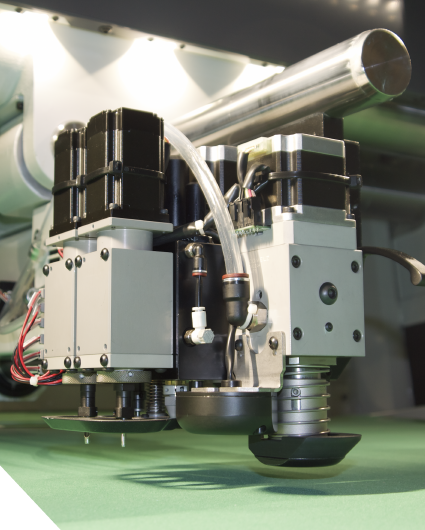

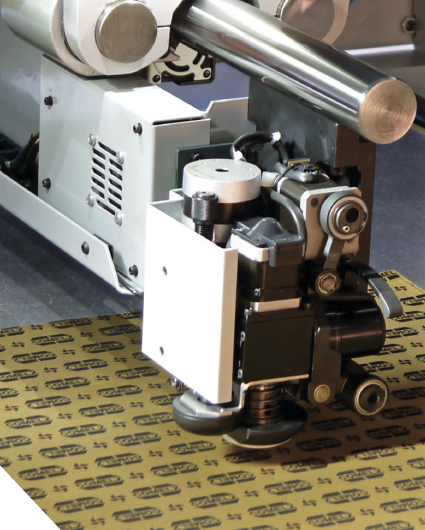

COMPACT MULTI-TOOL HEADS

Entirely developed, produced and integrated by Comelz, the tools are fast, robust, and reliable. In addition the tools are lightweight and compact improving the mechanical rigidity and allowing for quick and easy access to tool changing due to head rotation.

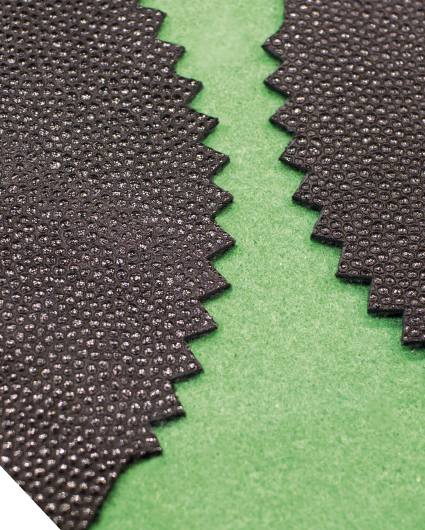

HIGH CUTTING EFFICIENCY

The knife height is controlled by a servo-system that allows the operator to adjust the knife height in the control panel and especially allows for dynamic and automatic compensation of the unevenness of the cutting area. This guarantees accuracy and high cutting efficiency reducing wear and tear on blades and cutting mat.

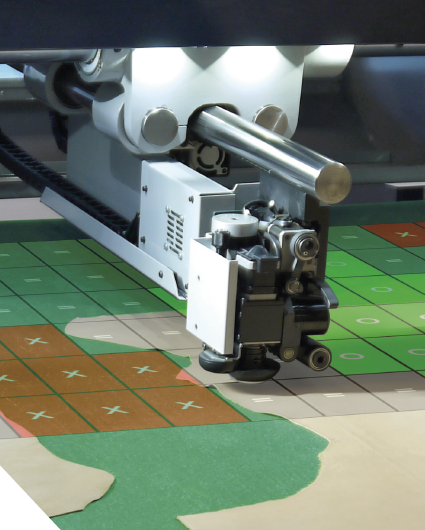

STOP&GO FOR CUTTING CORNERS

The Stop&Go patented system, available in the pneumatic Comelz oscillators, speeds up the execution of fragmented corners because it allows the blade to place in vertical controlled position during every oscillation, in order to get in and out the material during the cutting of corners without moving the head vertically, which is slower.

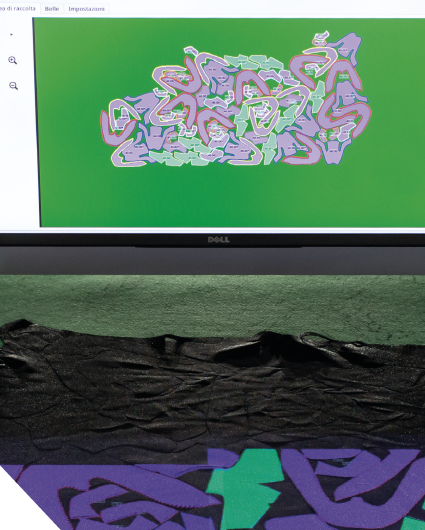

VISION CC

The Vision CC functionality allows, through the use of a camera and the special COMELZ cutting mat, to check each single advancement of the material to be cut to eliminate any errors due to the movement phase of the belt.

REMOTE SERVER

To fully exploit the auto-nesting software, a dedicated calculation server is available that can reduce time and increase the number of nesting solutions calculated.

ASSISTED PICK

With a touch screen and a dedicated software you can easily identify parts with different size of parts of different articles, send back into the bill of order parts that were potentially damaged, but also control the cutting machine parameters (knife hight, speed, etc.) directly from the collection position. With the aid of high quality LCD projectors, the collection assistance system can be integrated. By projecting different colors on different pieces of measurement, or pieces of different items in the same area to optimize the yield of the material, it is easier to identify and speed up the collection.

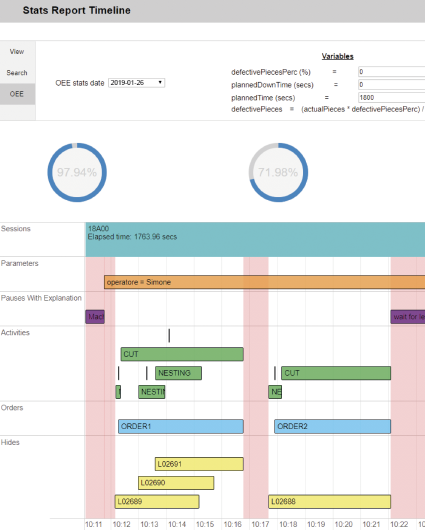

STATISTICS

It allows the complete report of the machine both in terms of production and total efficiency OEE (Overall Equipment Effectiveness). The information is presented with a simple and intuitive graphic interface, but can also be exported to third party programs in standard formats (html, json, csv, etc.).

VISION SN

Automatic placement software on materials that have known references (logos, recurring drawings, etc.) which must result in precise alignment of the cut piece. As an additional module, VISION DS allows you to automatically manage the distortion of geometries, so that any references on the material are always aligned and centered, typically belts.